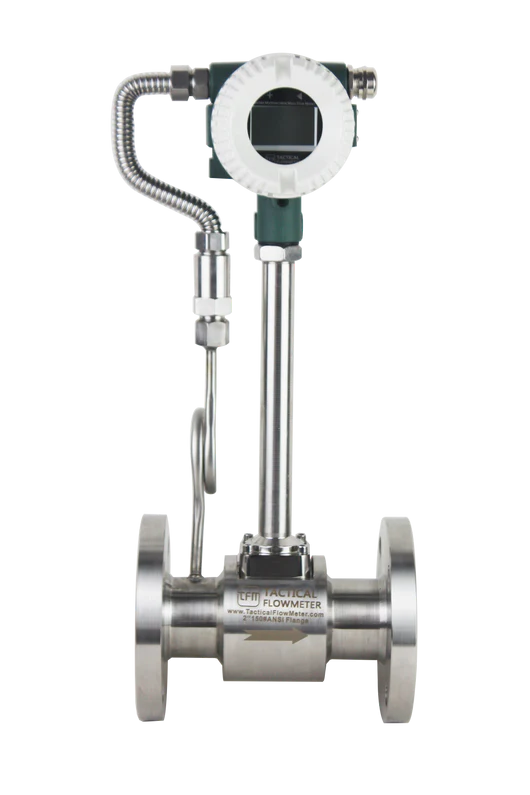

In the world of flow measurement, precision and versatility are paramount. Engineers and operators rely on advanced technologies to ensure the accurate monitoring and control of fluid processes. One such technology that has gained prominence in recent years is the multivariable vortex flow meter.

This innovative device offers a complete solution for various flow measurement needs, especially in industries where both mass flow and other process parameters are essential. Here, we'll explore five key applications of these vortex flow meters.

General Flow Measurement

Multivariable vortex mass flow meters are widely used in applications where the measurement of fluid flow is a fundamental requirement. They provide real-time data on flow rate, which is critical in industries such as water treatment, petrochemicals, and food and beverage. The integration of multiple sensors in these meters allows for the simultaneous measurement of flow, temperature, and pressure, ensuring precise and reliable results.

Steam Flow Measurement

The accurate measurement of steam flow is vital in various industrial processes, including power generation, manufacturing, and HVAC systems. These flow meters excel in this application, as they can determine both mass flow and energy flow rates, allowing operators to optimize their systems for energy efficiency and cost savings.

Compressed Air Monitoring

In industries that rely on compressed air, it's essential to monitor and control air consumption. These flow meters offer a cost-effective solution for accurately measuring compressed air flow, enabling better management of resources and identifying potential leaks or inefficiencies in the system.

Gas Flow Measurement

In the oil and gas sector, multivariable vortex flow meters are indispensable for measuring natural gas and other gases. These meters can provide mass flow rates for gases, which are essential for custody transfer applications and environmental compliance. Additionally, they offer the advantage of measuring temperature and pressure simultaneously, ensuring accurate data under varying conditions.

Chemical Process Control

These flow meters find a niche in chemical processing plants. They are used to measure and control the flow of various chemicals, ensuring that precise amounts are mixed to meet specific product requirements. The combination of flow, temperature, and pressure measurements allows for better process control and optimization, leading to higher product quality and reduced waste.

The End Note

In all these applications, multivariable vortex mass flow meters demonstrate their versatility and reliability. They are designed to withstand challenging conditions and provide consistent, accurate data even in the harshest environments. Their ability to measure mass flow and additional process parameters in a single device simplifies installation and reduces maintenance costs.

Their ability to measure mass flow, temperature, and pressure simultaneously makes them an invaluable asset in industries where precision and efficiency are paramount. Whether it's monitoring steam, gas, compressed air, or chemicals, these meters deliver dependable results that can lead to improved processes and substantial cost savings.