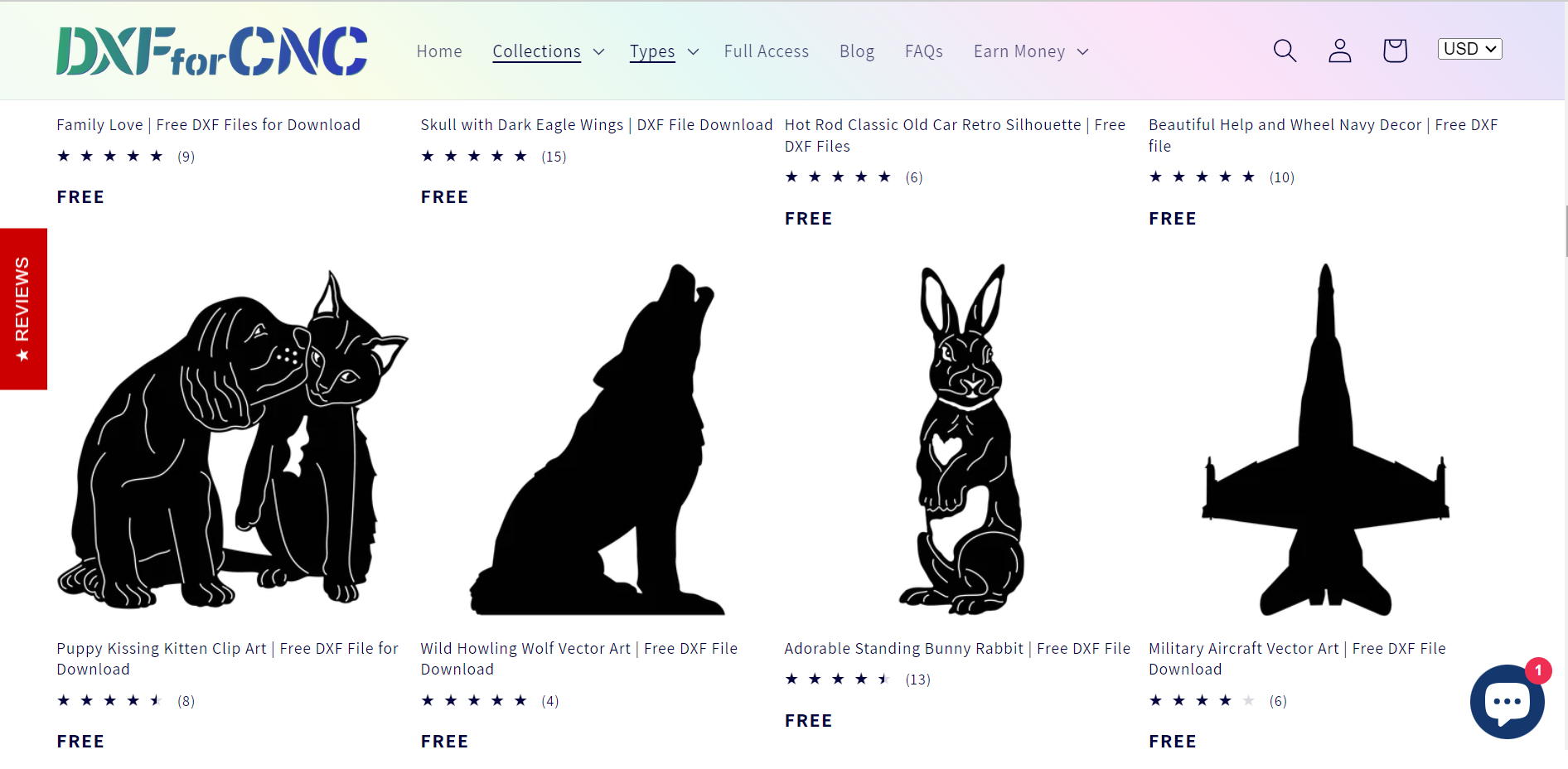

Are you looking for a way to turn your design ideas into reality without breaking the bank? Look no further than affordable laser cutting! With access to free downloadable DXF File Free Download , you can create budget-friendly projects with professional-grade precision. But where do you start? In this blog post, we'll cover everything from the basics of laser cutting to choosing the right machine and even provide project inspiration. So buckle up and get ready to unleash your creativity with affordable laser cutting!

What is Laser Cutting?

Laser cutting is a precise and efficient method of cutting various materials using a high-powered laser beam. The process involves directing the laser onto the workpiece, which then melts Free DXF File , vaporizes or burns away depending on the type of material used.

There are different types of lasers that can be used for cutting, including CO2 and fiber lasers. CO2 lasers are typically used for non-metallic materials such as plastics and wood, while fiber lasers can cut through metals with ease.

One advantage of laser cutting is its ability to create intricate designs with clean edges without the need for additional finishing techniques. Laser cutters also have minimal waste due to their precision, making them an eco-friendly option.

Laser cutting has become increasingly popular in industries such as manufacturing, architecture and fashion design due to its versatility and accuracy in producing complex shapes and patterns.

Types of Laser Cutters

When it comes to laser cutting, there are several types of machines available in the market. Each type has its own unique features and benefits that cater to different needs and requirements.

The first type is CO2 laser cutters which use a gas mixture of carbon dioxide, nitrogen, and helium to create extremely precise cuts. This type is ideal for cutting materials like wood, acrylics, plastics, and textiles.

Next up are fiber laser cutters which use a series of lenses and mirrors to direct the laser beam onto the material being cut. They are perfect for cutting metals such as aluminum or steel.

Another popular option is the Nd:YAG laser cutter which uses a crystal made from neodymium-doped yttrium aluminum garnet that converts light into infrared radiation. This machine is ideal for precision work on small parts or thick materials.

There's the UV laser cutter which utilizes ultraviolet radiation to make very fine cuts with precision accuracy. It's best suited for working on delicate materials such as glass or medical devices.

Choosing the right type of laser cutter depends entirely upon your specific needs and budget constraints. So take some time to research each one before making your final decision!

What are the Advantages of Laser Cutting?

Laser cutting has become a popular method for creating precise cuts on various materials such as wood, metal, and acrylic. But why choose laser cutting over traditional methods? Here are some advantages of laser cutting:

Laser cutting offers high precision and accuracy. The beam width is narrow, allowing for intricate designs to be cut with great detail. This means that you can achieve sharp edges and smooth finishes which would have been difficult to achieve using other methods.

It is a fast process as the laser beam quickly cuts through the material without any physical contact. Compared to traditional cutting methods like sawing or drilling which require time-consuming set up and slow progress in terms of actual work done.

It allows for greater versatility in terms of design possibilities as lasers can easily cut non-linear shapes while maintaining accuracy.

Lastly , Laser Cutting also reduces waste by minimizing errors caused by human error or incorrect calculations during the design phase - saving both time and money

These advantages make laser cutting an attractive option when looking for efficient ways to create high-quality pieces at affordable costs!

How to Choose a Laser Cutter

When choosing a laser cutter, it's important to consider various factors in order to make the right decision for your needs. First and foremost, you'll want to think about the size of the machine and how much space you have available. Some models are compact enough for a desktop setup while others require more floor space.

Next, consider the power output of the laser cutter as this will dictate its ability to cut through different materials with varying thicknesses. You'll also want to look at the maximum cutting area and whether or not it can accommodate larger pieces if needed.

Another key factor is software compatibility – ensure that your chosen model can be used with design programs such as Adobe Illustrator or CorelDRAW. Ease of use is also an important consideration; some machines may require extensive training before operation while others offer more intuitive interfaces.

Don't forget about safety features like automatic shut-off switches and enclosed work areas that protect users from harmful fumes produced during cutting processes. By carefully considering these factors, you can choose a laser cutter that best suits your individual needs and budget.

Getting Started with Laser Cutting

Getting started with laser cutting can feel intimidating, but it doesn't have to be. The first step is to choose the right laser cutter for your needs. Be sure to consider factors such as size, power, and price when making your selection.

Once you've chosen a laser cutter, it's important to familiarize yourself with its features and capabilities. Read the manual carefully and practice on scrap materials before working on your actual project.

When preparing your design for laser cutting, make sure that all lines are closed and any text is converted into paths or outlines. This will ensure that the machine cuts everything correctly.

Before you start cutting your material, take proper safety precautions by wearing protective equipment such as goggles and gloves. Also make sure that the workspace is well-ventilated in case of fumes or smoke.

Don't be afraid to ask for help if you run into any issues during the process. There are many online communities dedicated to laser cutting where you can seek advice or share ideas with other enthusiasts.

Remember – getting started with laser cutting may seem daunting at first, but with practice and patience anyone can master this amazing technology!

Projects You Can Try with Your New Laser Cutter

Now that you have your new laser cutter, it's time to get creative and start some fun projects! Here are some ideas to help jumpstart your imagination:

1. Customized Jewelry - With the precision of a laser cutter, you can create intricate designs on metal or wood to make unique earrings, necklaces or bracelets.

2. Personalized Home Decor - Give your home a personal touch with customized picture frames, wall art or even lamps made from acrylic sheets.

3. Puzzle Making - Create custom puzzles for family game night by cutting out pieces from cardboard or wood. You can use pre-made patterns or design your own!

4. Engraved Glassware - Add an extra special touch to housewarming gifts by engraving personalized messages onto wine glasses, tumblers or shot glasses.

5. Model Building - Use thin wooden sheets cut with a laser cutter to create precise pieces for model airplanes, trains or cars.

These are just a few examples of the many possibilities when it comes to using a laser cutter for DIY projects! Let your creativity flow and see what amazing things you can make!

Conclusion

Laser cutting has revolutionized the way we create and design various materials. With affordable laser cutters available in the market, it has become easier for anyone to access this technology. By following the steps outlined in this article on how to choose a budget-friendly laser cutter and where to find free downloadable DXF files, you can start creating your own projects today.

Remember that safety should always be a top priority when using laser cutters. Always wear appropriate protective gear and follow manufacturer instructions carefully.

So go ahead and explore the world of laser cutting – there are endless possibilities waiting for you!