Make the smart choice for sensitive equipment that can be transported, stored, and protected with Aluminum enclosures. It works well in applications exposed to intense electromagnetic fields, corrosive conditions, and harsh temperatures.

What is all about Aluminum Extrusions?

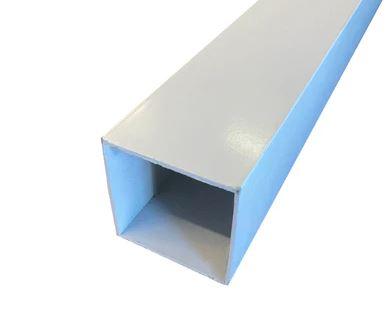

The most prevalent element in the Earth's crust, Aluminum is a metallic element with countless industrial uses. The term "extruded" describes a particular industrial process that uses a die to form a material, in this case, Aluminum, but it may also be plastic, clay, or even dough. To produce a specific form or profile, the Aluminum is forced through the mould once it has softened.

Aluminum Extrusions offer a number of distinctive advantages, such as corrosion protection, superior strength, a high potency ratio (strong yet lightweight), and a smooth, one-piece design that makes repairs and replacement easier.

Benefits of Aluminum Enclosure Parts

Extruded Aluminum operates effectively in a variety of settings. The material itself is Ultraviolet resistant, which ensures that it will maintain its solid state when exposed to the sun and shields your PCB components from damaging ultraviolet rays. In some cases, extruded enclosures even include a watertight gasket as an additional layer of defence in outdoor settings.

Speaking of delicate interior components, Aluminum enclosure parts are excellent at preventing them from being harmed by a range of external elements, such as moisture and dust. Aluminum enclosures have special characteristics that help make them more weatherproof. For instance, a grooved outer design encourages quicker heat dissipation while the IP66-graded gasket protects against dirt and jet-sprayed water.

Aluminum is used extensively for a reason—highly it's durable. The material is extremely unlikely to break or warp because of the extrusion method, which guarantees that the final product is significantly thicker and more damage-resistant than normal roll-form Aluminum. For added durability, our Aluminum enclosures also have metal end caps.

Best Aluminum Enclosure Parts

5052 Aluminum - H32

The best Aluminum enclosure part to use for metal sheet work is 5052, which is also very simple to shape at room temperature. Due to its high flexibility, this material can manage small radii. Aluminum alloy 5052, which cannot be heated, is easily joined together using customary techniques. It has good forming properties and is corrosion resistant, particularly saltwater resistant.

6061 Aluminum T6

A versatile alloy, aluminum is frequently used in extrusions and is also offered as sheet metal. It's also quite simple to process 6061 aluminum.

MIC -6 Aluminum

Cast aluminum plate MIC-6 is renowned for its consistency and stability between plates. It is preferred for machining and base plates because of its improved smoothness and dimensional accuracy on the thickness.

Best Aluminum Extrusion Company for better service

Being one of the best Aluminum extrusion companies we have a wide selection of completely customizable Aluminum extrusions, which are well-liked in a variety of industries, including the automobile, communications, and more frequently connected with high-end audio equipment. In addition to offering standard sizes, we can also cut your extruded Aluminum enclosure to the precise length needed for your purpose. We can also deliver a fully customized Aluminum extrusion thanks to our CNC machining, anodizing, and printing services.

You can always rely on U-Build-It for help in identifying the best enclosures for your project. In addition to extruded Aluminum housings, we also have comparable Aluminum enclosures that each have a great number of advantages. As always, we'd be pleased to assist you in deciding which choice will work best in your particular situation.